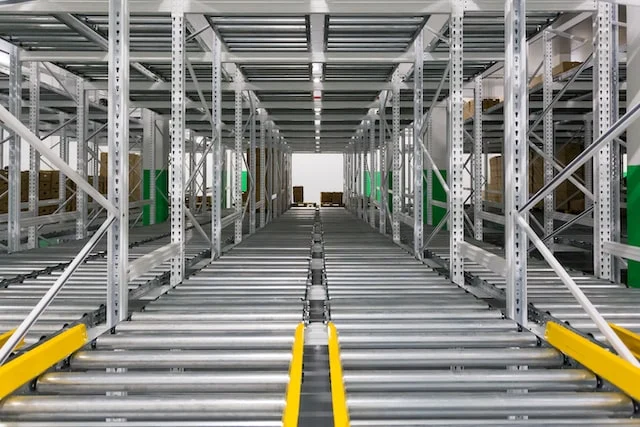

Our Other Warehousing Services

Re-engineering of Existing

When growing sales demand more from your facilities, LPC International is here to help. We specialise in re-engineering existing facilities to increase storage capacity, expand product range capabilities, and improve productivity. By mapping current processes, implementing new workflows, and integrating advanced warehouse management systems, we ensure your operations are streamlined and costs are reduced.

In many cases, extending the life of an existing facility can provide the time needed to plan for a new one. With the right equipment, processes, and material flow improvements, moving to a new site may not even be necessary.

LPC International combines expertise in facility optimisation with proven strategies to help businesses adapt and grow efficiently, ensuring you stay ahead of the demands on your supply chain.

Consultancy Support and Design

A smaller operation will still encounter many of the issues and problems of a larger operation. Alternatively, a company may want to improve the knowledge and capability of their operational team.

LPC can provide consultancy support to improve the warehouse layout and operation by working on site with the warehouse manager and senior team. A senior consultant will audit the operation and facility advising on the options for everything logistically or operationally related and work with you to produce the solution to your problems, and opportunities!

The warehouse layout may be a legacy that is experiencing diminishing efficiencies or simply that it is required to achieve greater capacity and or throughput. Warehouse enhancement might simply be a project to reduce costs and raise service levels. Whatever the requirements we can advise on a host of initiatives for the short term to the longer-term planning to improve warehouse efficiency.

What Does It Mean To Re-Engineer A Warehouse And What Does It Entail?

Re-engineering is the process of changing your current operation and set up to meet your current or future needs and business objectives. It usually starts with a need being identified –e.g. to increase storage capacity, improve productivity, reduce costs. However, the scope and ramifications will vary.

Re-engineering a facility is almost always cheaper than moving, provided what you require can be done. Don’t forget that physical changes are only one element, operational processes and IT systems are others, as are elements that are impacted or are affected by the warehouse operation such as purchasing and sales.

If you think you have the need to Re-Engineer your facility you will need to ask yourself the following questions:

Operational Layout

– Does the warehouse flow without constraints?

– Are materials straightforward and optimised?

ABC Classification

– Are your SKU’s correctly allocated?

– Are your product flows minimalised?

– Are you experiencing congestion areas?

Business Changes

– Do you need to accommodate new customers?

– Is there a requirement for increased picking?

– Introduce a packing operation to support e-commerce?

Storage Requirements

– Do you have the right storage media for the application?

– Is the storage layout optimised?

– Is it flexible and cater for growth?

– Are you getting efficient utilisation?

Re-Engineering

– Can physical changes be made to the facility?

– Can the facility be extended?

– What impact will growth have on operational life left in the warehouse?

– Is there opportunity to physically reformat the warehouse?

Storage Equipment/Media

– Is the storage media still fit for purpose?

– Does the type and layout of media meet future requirements?

– Is the space and height used – is there efficient use of the cube?

– Are you achieving industry standard KPI’s?

Audit

– Is the warehouse meeting KPI’s?

– Benchmark against industry standards

– Are you meeting orders?

– Are you being forced to double handle or search for items

– Do you have the right resource allocation?

Growing sales, new store openings, or supply chain challenges? LPC International helps you adapt by re-engineering facilities to boost storage, optimise workflows, and reduce costs. We can extend the life of existing sites or plan for future expansion—often eliminating the need to relocate.

Book a healthcheck today to turn growth challenges into opportunities.

Read Our Blog

How To Make Your Internal Warehouse Layout Most Efficient For Your Building Shape

Let’s turn that title on its head. The ideal is to work out your materials handling system first, and only then fit the building design around it. In an existing building, you may be limited in your ability to do this – but designing from the inside out as far as possible is key to maximising efficiency.

How To Design A Warehouse Layout That Will Work For Your Business

Every business at some point will consider designing or redesigning a warehouse facility to fix some bugbears and inefficiencies, to cater for expansion or simply as a result of relocation. This can be seen as a godsend by warehouse managers and an opportunity to start from scratch with the benefit of experience and hindsight.

How To Prevent Damage To Your Warehouse Racks

Warehouse pallet racking is critical to the efficient operation of a warehouse, as well-designed systems can increase productivity, versatility, and space. Preventing damage to your warehouse racking assets is, therefore, crucial. What steps can you take to avoid damage and downtime?