LPC use a number of software tools to demonstrate, simulate and model their designs. Real time modelling allows clients an overview of the proposed operation in the concept design phase and allows LPC an ability to confirm the capacities and improve the resilience of proposed systems. The use of these tools allows for the:

- Proving and refining design concepts.

- Testing what if scenarios.

- Identification of potential bottlenecks.

- Sizing of space and storage requirements.

- Determination of labour and MHE requirements.

- Provision of” fly throughs” to demonstrate visualisation of the operation.

- It is important to build flexibility into a design to allow for future developments and changes. The models LPC build are used to test the boundaries of the performance of the proposed concept and thereby assess its flexibility and resilience.

An added benefit of the modelling is that the models can be run in real time and using 3D graphics can provide movie files that enable the concept to be demonstrated to the operational team.

Inbound and Outbound Transport Flows

Purpose: To optimise the positioning of the Gatehouse to avoid vehicle queuing back on to the public highway – Inbound – and congestion within the site – Outbound and identify waiting times and resources requirements.

Description: Inbound vehicles arriving are split into three lanes – two for suppliers (green) and one for client’s own vehicles (blue).

Private Vehicles Flows Entering and Leaving Site

Purpose: To identify the effects of vehicle flows at shift change to determine road and junction layout to minimise effect on public roads.

Description: Cars arriving and departing at shift change – over three shifts.

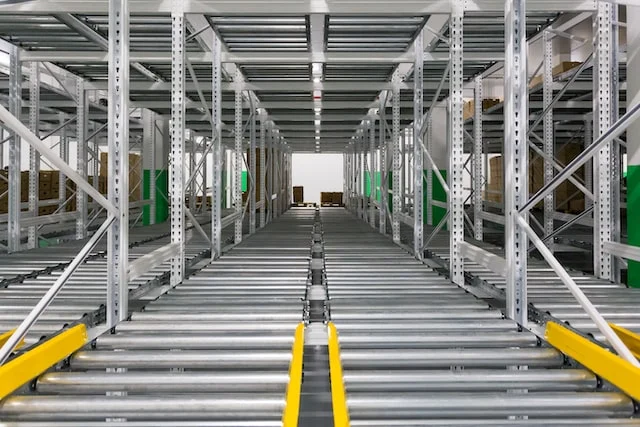

Pallet Conveyor System

Purpose: To identify bottlenecks and test potential changes to the system. This system is a pallet conveyor system linking a raw material and finished good stores with production.

Description: To identify the impact of varying pallet flows on the overall through put of the conveyor system and determine the buffer requirements.

Supplier Route DC Flyover

Fly Through: Supplier vehicle routing around a flow through Distribution Centre (DC) from Gatehouse to Gatehouse.

Description: Demonstrate the separate routing of supplier vehicles from entering site to dock for unloading via Resource Recovery Unit and exit of site.

Store Delivery Route DC Flyover

Fly Through: Store delivery vehicle routing around a DC from Gatehouse to Gatehouse.

Description: Demonstrate the separate routing of store delivery vehicles arriving back at the DC visiting the derv island, vehicle wash and Resource Recovery Unit prior to loading for the next delivery.

Read Our Blog

How To Prevent Damage To Your Warehouse Racks

Warehouse pallet racking is critical to the efficient operation of a warehouse, as well-designed systems can increase productivity, versatility, and space.

Grow Where You’re Planted: How To Optimise Your Warehouse Space For Growth Without Moving Premises

When your business is thriving, but your warehouse is too small for your rising stock levels, you face a dilemma. Moving to a new warehouse is expensive and logistically challenging

5 Keys To Effective Supply Chain Management

Efficiency underpins all successful supply chains. With modern customers and clients expecting rapid fulfilment – and prepared to shop elsewhere if goods don’t arrive quickly enough – every part of the supply chain needs to be meticulously monitored.