Our Other Materials Handling Services

It is important to build flexibility into a design to allow for future developments and changes. The models LPC build are used to test the boundaries of the performance of the proposed concept and thereby assess its flexibility and resilience.

An added benefit of the modelling is that the models can be run in real time and using 3D graphics can provide movie files that enable the concept to be demonstrated to the operational team.

When looking at materials handling the starting point is determining the scope of the project.

This can be summarised as:

- What you are handling

- Where are you moving it from and to

- How much are you moving

- How frequently are you moving it

LPC will:

Detemine and confirm the operational needs

Produce a specification setting out the requirement

Identify Suppliers and Prepare ITT/RFQ Documentation

Assist with Procurement Advise on Commissioning and Handover

Data Analysis

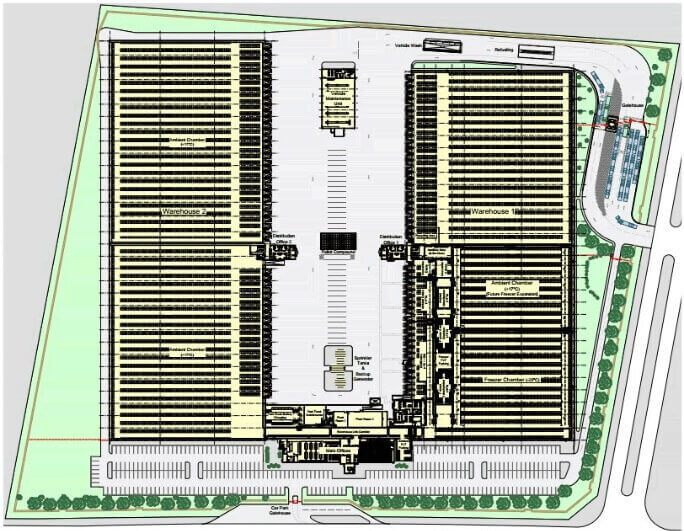

Data on your products and activities needs to be gathered and analysed. The analysis should consider not only activity such as orderlines, but also the cube being moved. Future demands need to be incorporated into the analysis looking at perhaps a 5 to 10 year design horizon.

From the analysis you can determine the business requirements and taking account of your service levels and customer expectation you can build a DILO (Day in Life of) for your operation. The DILO together with the material flows from the analysis will allow you to design the operation and determine the equipment and numbers and types of MHE that you will need.

It is important to build flexibility into a design to allow for future developments and changes. The models LPC build are used to test the boundaries of the performance of the proposed concept and thereby assess its flexibility and resilience.

An added benefit of the modelling is that the models can be run in real time and using 3D graphics can provide movie files that enable the concept to be demonstrated to the operational team.

When looking at materials handling the starting point is determining the scope of the project. This can be summarised as:

- What you are handling

- Where are you moving it from and to

- How much are you moving

- How frequently are you moving it

The operational design selected needs to be flexible to efficiently handle average and peak periods and to be capable of expansion for the future. It is often challenging to identify what future growth might look like or there is uncertainty over the reliability of the data. It can be very helpful to undertake modelling and simulation to test scenarios and gain confidence in the design.

Growing sales, new store openings, or supply chain challenges? LPC International helps you adapt by re-engineering facilities to boost storage, optimise workflows, and reduce costs. We can extend the life of existing sites or plan for future expansion—often eliminating the need to relocate.

Book a meeting today to turn growth challenges into opportunities. Why you should book a meeting with us:

- 40+years of experience.

- Speaking to a Director.

- No obligation, informal discussion.

- Worked in most business sectors.

Read Our Blog

Big Data and Logistics

One would think that the more data we have available, the better would be our decision making capability. However, we are at risk of being swamped with data because of the immense capability of disparate devices now capable of being linked through the Internet Of Things (IOT).

How To Analyse Your Logistics Strategy In 8 Easy Steps!

How efficient and adaptive is your logistics strategy? To develop a plan, or assess the efficiency of an existing one, every element of your logistics operation should be assessed and monitored to establish costs. KPIs and identify areas where savings can be made.

What Is A Circular Supply Chain In Logistics?

The term ‘circular economy’ has been increasingly discussed at a local and international level. In the UK, its estimated that transitioning to a circular economy could help meet up to 80% of the country’s carbon budget.